KiwiCo Portfolio

My invention, the Pixel Art Lightbox resulted in one of KiwiCo's very first product patents, for uniquely using a cell phone as an animated light and sound source for a Lite Brite inspired toy, click on the image above to go to the live page!

Product Case Study:

Skills and processes used in design thinking, prototyping to manufacturing

Design thinking:

Backlit peg art toys on the market are similar, how can we differentiate and being something new, engaging, and educational that can be patent protected?

Thinking outside of the box, we need a backlight source, what can be used that delivers on all the criteria? What could we do that would be low cost? Then the wildest thought, what about NO cost-- what might people already have, especially something old that they might even throw away?

We tried an old cell phone, and realized that by creating and playing a peg pattern specific video, that would allow animation AND audio, and since both can be delivered online, that it could be an ever updating platform. My favorite animated peg pattern features the rocketship with the historic NASA audio of the first manned moon landing!

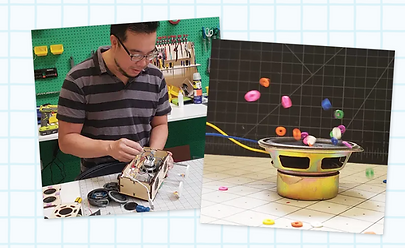

Prototyping/part design:

-

3d modeling in Solidworks

-

Laser cutting (flat wood, flat plastic parts)

-

3d printing (plastic parts

-

CNC cutting (for peg templates)

-

hand machining

-

graphic design in Illustrator/Photoshop

-

animation and video/sound editing (for cell phone video that animates pixels, In Da Vinci Resolve)

-

web app design (prototyped in Wix website, mobile layout)

Manufacturing and software:

-

Lasercutting

-

injection molding

-

diecutting

-

laminating

-

direct vendor communication, coordination and management through production

-

web app development

Pixel Art Lightbox

Flex and Fly

Plane Launcher

Another one of my inventions, the patented flexible and functional bendy memory wing!

Design thinking: We chose flexible EVA foam over balsa wood for durability. What new functional opportunities did this material change introduce?

We thought about just making the control flaps movable, but what would happen if the entire wing was malleable and could hold any contortion or twist, would it still fly? Experimentation proved yes!!

And the first "action figure wing" was born: bend your own airfoil, conservatively or cartoonishly, and see how your wing shape creation flies! Do it over and over again to learn about how wing shape affects flight and maneuvers, whether silly or seriously shaped, you learn something about your aerodynamic creation with each shape and launch. Another patented idea resulted from this out of the box thinking!

(click on image above to go the live page)

Imagination running wild, with motorized and gravity sped sledding, as well as an innovative chalkboard skating pond: chalk skates leave tracks, and felt trees are used to erase them, making the trees more and more "snow" covered the more you use them!

Mechanical design solutions:

-

developed a flexible timing belt, with evenly spaced sprockets that contained integrated magnets

Exceeded sales and sold out before the season was over! Click on the image to go the live page!

Winter Wonderland

Advent Calendar

Motion Sensing Spider (re-boot)

Build it yourself for age 9+, Learn electronics, build a motion sensor and motorized drivetrain.

Goals with the re-boot (V2 vs V1):

-

improve mechanical reliability

-

improve electronic sensing

-

improve battery life

-

address excessive heat

-

improve build quality/perceived value

Engineering and design solutions:

-

cost constraint: As with V1 (V1 preceeded my involvement), with V2 we could only afford a one-direction motor controller. With V2, we changed from a rubber band to a coiled torsion spring, iterated this custom spring solution directly with China vendor providing Solidworks CAD authored 3D dielines

-

changed from direct drive to a gear drive, and chose a more efficient motor, which improved mechanical reliability and battery life. Custom gears modeled in Solidworks, managed China IM vendor through samples through production

-

changed from a stock IR motion sensing controller to a custom programmed IC to our specs. Together with the above improvements false triggers were eliminated and battery life improved by more than 10X

-

Changed from a cardboard box enclosure to lasercut wood and diecut PP sheet, increasing perceived value and upleveling to a higher price point.

Results:

Exceeded sales and sold out before the season was over! Click on the image to go the live page!